Address:

Beogradski put b.b.

14221 Valjevo, Serbia

Phones:

+381(0) 14 283 092

+381(0) 14 283 104

Fax

+381(0) 14 283 104

E-mail:

office@comprex.rs

Address:

Jurija Gagarina 176,

11070 Belgrade

Phone / fax:

+381(0) 11 3189 667

Cell:

+381(0) 69 5426 102

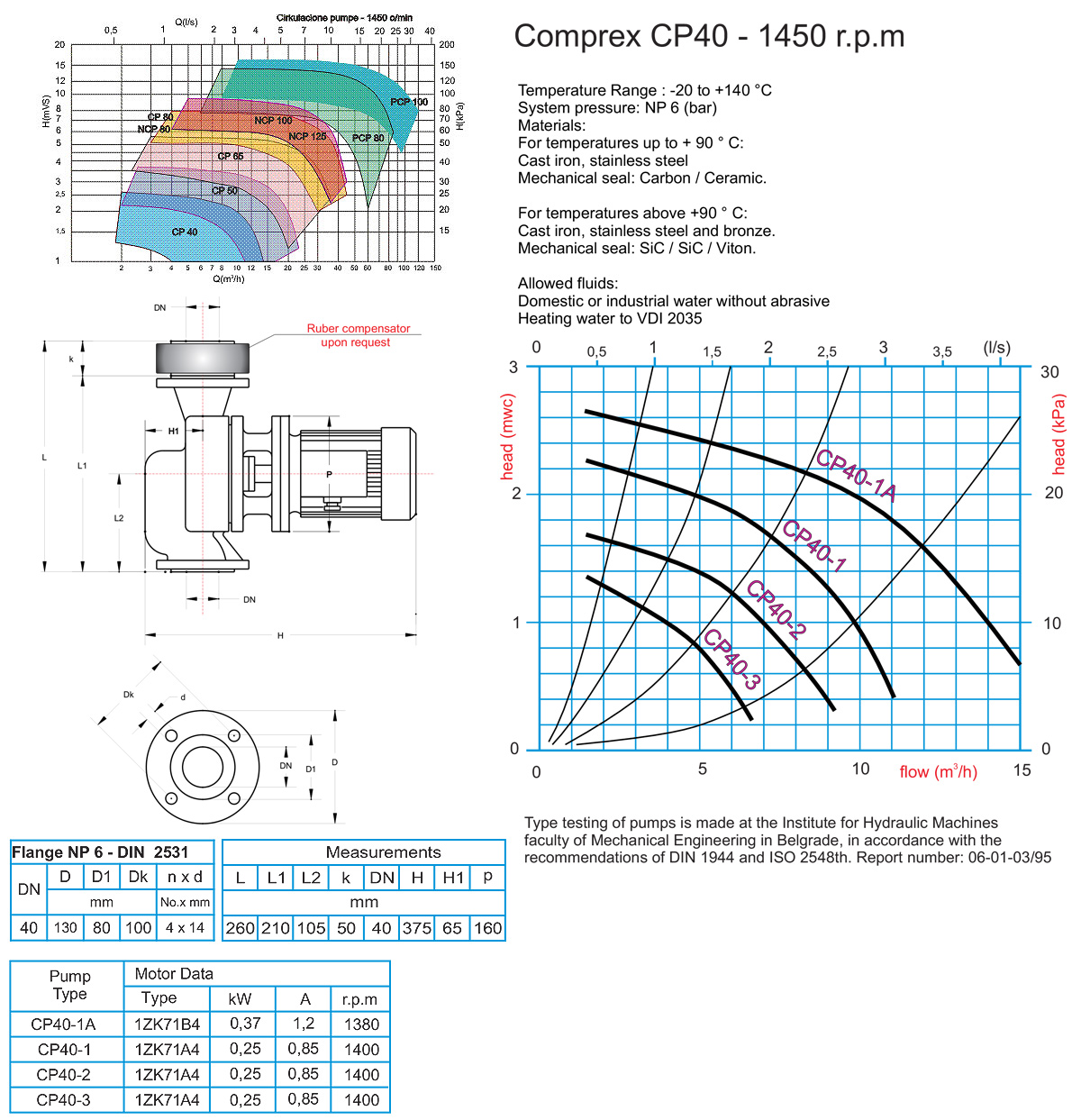

Circulator pumps COMPREX intended primarily for circulation of hot water in heating and cooling water and condensate. CP model pumps are intended primarily for installation in the secondary sub-station which requires a minimum level of noise, and the CPL model fitting in the boiler room and primary substations, and where greater efforts are required and flows.

Circulator pumps COMPREX are designed as single-stage centrifugal (spiral) pump type. From the usual structure of circulation pumps with wet rotor, they are built with classic motor (with dry rotor).

Suction and discharge hole pump, with standard flanges are “in-line" performance, or in one axis. If necessary set of impeller, together with the console and partition wall, can be dismantled and that the pump housing to remain in the pipeline. His products, COMPREX meets the requirements of the widest in the central heating and air conditioning and domestic hot water supply.

Pump body, impeller, the console and partition walls are made of high quality cast iron. Headset shaft is of alloy, stainless steel. Mechanical seal is a product of the world's most famous manufacturers. Circulator pumps COMPREX are mounted directly in pipeline of hot water heating system or in some branches of the pipeline. Connection with the pipeline pump is realized through standard flange NP6 (for CP and CPL) or NP16 (for PCP and PCPL) for the corresponding nominal diameter of DN, but the pipeline DN must be identical to the DN pump.

On the suction side piping connection is achieved with sealing ring and 4 screws with nuts, and the discharge side with 4 screws that come with the pump.

For a peaceful and silent operation it is desirable that the pumps are installed in the flat part of the pipeline or at a distance from the knee at least 5 to 10 x DN.

Fitted to both the pressure and in the return line, with the lowest absolute pressure in the system must behigher than the vapor pressure at operating temperature. Pumps can be installed in all positions except in position with the engine down.